DEMISTERS / MIST ELIMINATORS

Effective Mist Eliminators for Industrial Applications

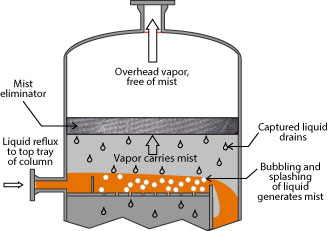

Mist elimination can be defined as the mechanical separation of liquids from gases. The equipment used for the removal of this entrainment is referred to as a mist eliminator or demister.

In the chemical process industry there are a number of processes where gases and liquids come into contact with each other and whenever this happens the gas will entrain some amount of liquid particles. This liquid phase which gets carried away into the gaseous phase can lead to a number of problems like loss of product, equipment damage, process inefficiency etc. and needs to be eliminated.

Finepac meshpad mist eliminators can provide liquid entrainment solutions in a variety of equipments including:

- Scrubbers & distillation columns

- 3 phase separators

- Knock out vessels

- Evaporators

- Desalination plants

- Steam drums

- Gas dehydration plants

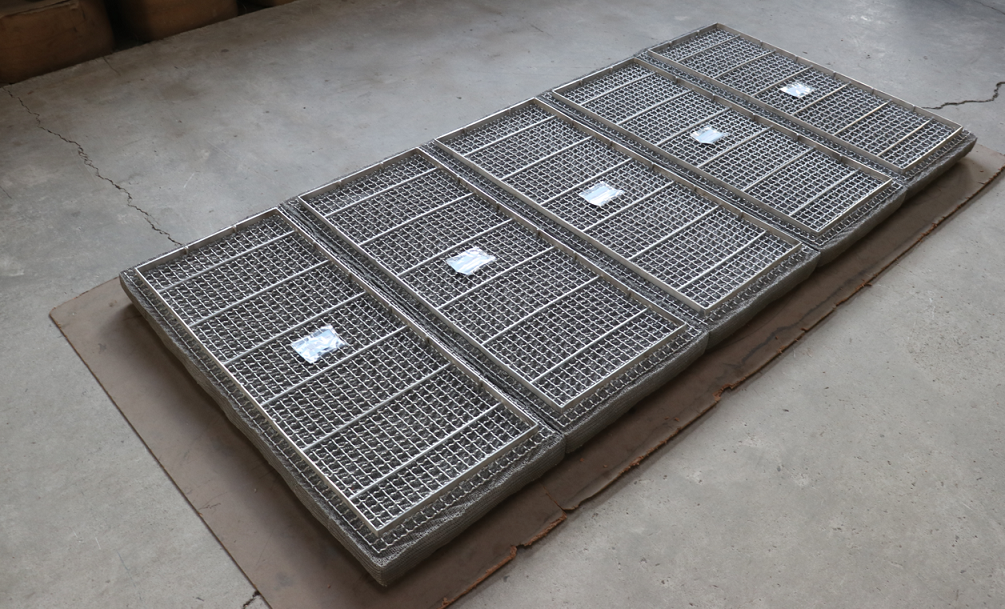

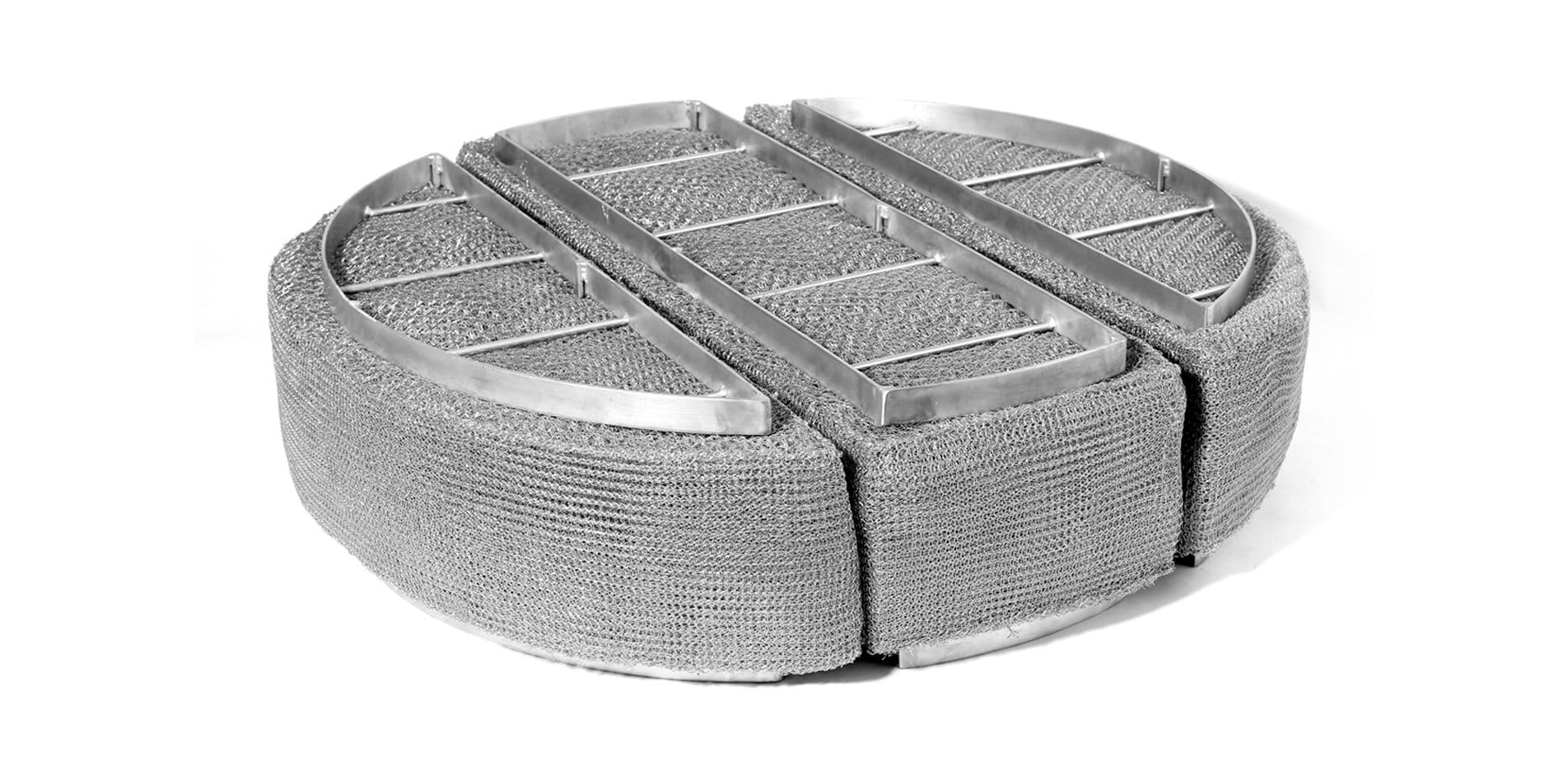

Wiremesh meshpad mist eliminators consists of a pad of knitted metal or plastic wire mesh usually sandwitched between grids for mechanical support. Units above 600 mm diameter are normally split into sections in the range of 300 to 400 mm to facilitate installation through a normal vessel manway. The pads are cut slightly oversized to ensure a snug fit and eliminate possibility of a vapour bypass either between sections or between pad and vessel wall.